In previous articles we have told you what the products of the Briki®, line are, and how they have been designed and manufactured by the innovative Swiss company Meteca. We took the opportunity to chat with them so they could tell us how, with their modules, you can quickly switch from prototyping to the creation of a finished product.

“Obviously it depends on the type of project, the complexity, the scope and the technologies involved. In general we try to give a standard time to the project and from this starting point, we see how it can be reduced thanks to the use of our technology,” Dario Trimarchi and his team of Meteca engineers explained. “The work of design and prototyping can encounter several obstacles in its path, one of these is the need to relate to the differences in legislation of the countries in which the final product will be used.

Typically the process of making a product from a prototype requires a set of tests. These tests allow the operation and compliance with regulations to be validated for all the operating conditions for which the product needs to be used.

From country to country, regulations and legislation may differ for emission limits, bands, powers, etc… , it will be necessary, therefore, to perform this set of tests several times and with different parameters. This means, for example, that what is legally valid for the European CE/RED certification may differ in several places from what it is for the American FCC certification”.

The prototyping process may encounter several problems that can be overcome easily or reduced with the use of Briki modules, Meteca’s technicians explained how: “The testing, validation and compliance process of a device is time-consuming and costly. It is rare that a prototype “passes” the tests at the first attempt, different parameters may be outside the limits, it is usually necessary to perform a careful analysis of the results obtained, and then implement design changes to correct those that don’t conform.

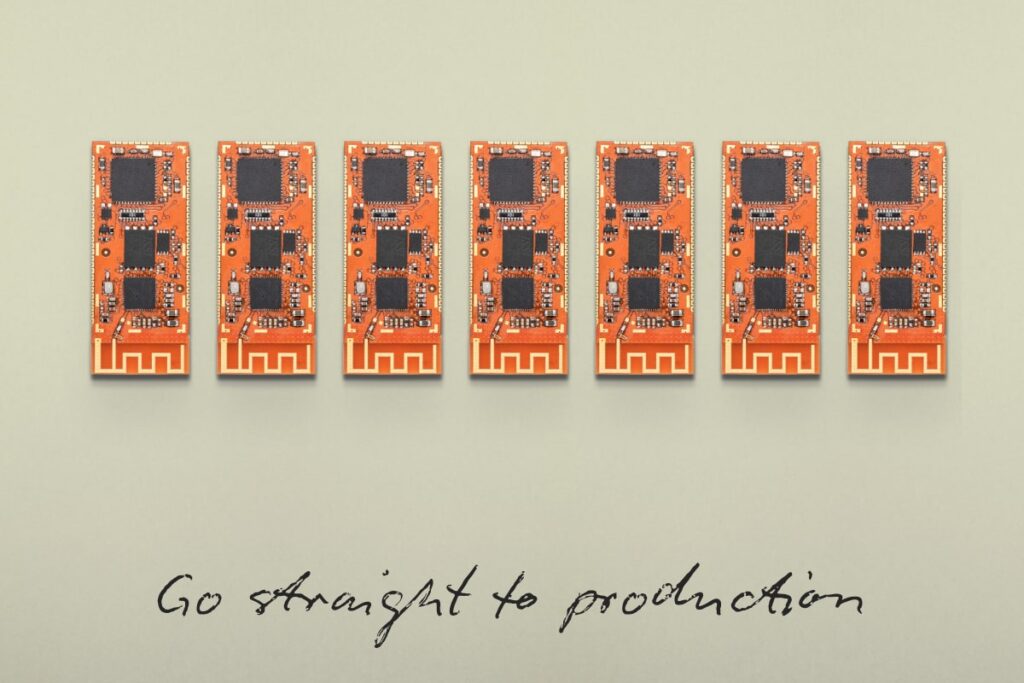

Once these changes have been implemented, it will be necessary to perform the prototyping process and related tests again. All these operations may cost several thousand euros and months of work. By immediately using a solution such as the Briki MBC, which can be used both for prototyping and for production, you can drastically reduce the times and difficulties of both, and accelerate production by allowing the market to be attacked faster than competitors.

How? First of all the module on the development boards is the same that will then also be used in production, and has been pre-certified and validated for the most common fields of use. In addition, the technological complexity has been completely focused on the MBC module, which allows those who develop their final solution with Briki to greatly lighten the design work with a further saving of time.

Do not forget that a device based on a Briki MBC will not be subject to a complete certification test, but only to a part of it, this makes it possible to minimize the time and costs for obtaining a certification for your product, saving months of work and thousands of euros”.

Thanks to the advanced technology of Briki and the speed of application of the design and prototyping process, you can put on the market an innovative product saving time and money, two key factors to defeat the competition and have a higher budget to invest, for example, in marketing.

For further information on the IoT world, please contact Meteca here.